Mobility Division

It has also adopted various initiatives for achieving a low-carbon society by selling equipment and materials used in the field of rechargeable batteries, including lithium-ion batteries, solid-state batteries, and fuel cells, which are mainly mounted onto automobiles.

It also supplies and upgrades automated robot-based systems, develops control systems for not only automated warehouses and AGVs, but also all types of distribution systems and WMS/WCS, etc., and provides a wide range of solutions utilizing leading-edge technologies.

Proposals for a wide variety of equipment from Japan and overseas

We offer equipment used in many different manufacturing processes involved in the production of automobiles, from the upstream to downstream processes. These processes range from casting, forging, machining, and stamping to injection molding, welding, painting, and assembly inspections. Through this equipment, we propose optimal solutions to our customers.

(Photo:Provided by UBE MACHINERY CORPORATION, LTD.)

Stabilizer testing machine

Engineers and supervisory technicians on hand to undertake commissioned construction

Complete on-site safety management and process management are required to complete work within the limited period for equipment installation. We have in-house supervisory engineers who can handle large-scale construction projects, and our experienced staff provide our customers with a wide range of support, from the preparation of construction-related documents to process and on-site management.

Tandem press line(Photo:Provided byHitachi Zosen Fukui Corporation)

High frequency induction furnace(Photo:Provided by Fuji Electric Co., Ltd.)

Turnkey & maintenance services for automobile plants at oversea

―― Automotive Project Department

For all type of vehicle production, including EV/HV/PHV/FCV, we have provided the turnkey services of production line for our customers oversea plants.

Related our turnkey services, we have a lot of experience to optimally arrange the global logistics and supporting the tax reduction scheme such as EPA / FTA.

After the plant starts operation, we can provide a long-term production support system for overseas automobile plants by supplying repair parts, maintaining equipment in collaboration with local engineering companies, and modifying equipment in connection with the introduction of new models.

Years of engagement in vehicle-mount batteries

―― Secondary battery

The automotive rechargeable battery market continues to grow along with the automotive market trend of largely shifting from internal combustion engine vehicles to electric.Sojitz Machinery provides domestic and overseas customers with rechargeable battery manufacturing equipment for hybrid vehicles (HVs), plug-in hybrid vehicles (PHVs), electric vehicles (EVs), and fuel cell vehicles (FCVs).Our engagement in the rechargeable battery field dates back to the days when the market was just starting to grow in the mid-1980s. Since then, we have accumulated many achievements over the years, and are currently supplying mainly back-end (assembly process) equipment to automobile and battery manufacturers.In addition to rechargeable battery platforms, we also provide solutions for EV, HV, and PHV platforms.

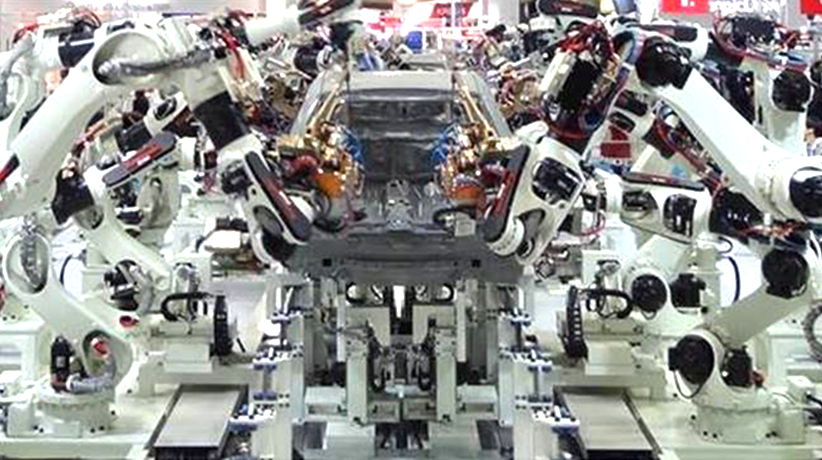

Provision and upgrade of automated robot-based systems

―― Robotics solution services

We provide automated production line solutions centered around automobile manufacturers, including painting, welding, and transportation systems that have been upgraded with various types of robots for both new facilities and aging machines.

One-stop provision of distribution system solutions

―― Distribution system solution services

We sell material handling units for the purpose of automating and reducing manpower for the storage, transportation, and picking duties carried out in distribution warehouses.We provide our in-house engineering skills for all types of material handling units regardless of the manufacturer, and offer one-stop solutions encompassing all services, from operation improvement proposals for distribution warehouses and software development to installation and after-care services.